At FoamWorks, we bridge the gap between architectural vision and tangible, high quality building components. We specialize in the precision manufacturing of custom Expanded Polystyrene (EPS) foam architectural shapes that are integral to Exterior Insulation and Finishing Systems (EIFS). Our mission is to provide durable, dimensionally accurate, and ready-to-install decorative elements in your building project.

Our story: from installation to innovation

This firsthand installer’s knowledge was further built upon with the acquisition of FoamCAD’s manufacturing processes of EPS shapes. Although we’re a new name in the business, we already have four years of process development under our belts which guarantee consistent results. FoamWorks is the culmination of that experience and innovation

“Over 15 years”

“Guarantee consistent results”

Our journey in the EIFS Construction industry spans over 15 years. Our founder’s extensive experience on the installation side gives us a unique and practical perspective. We understand the challenges installers face - from the need for consistent pieces to the need for a durable end product.

How We Achieve Architectural Precision

Our commitment to excellence is built on state-of-the-art technology and meticulous processes

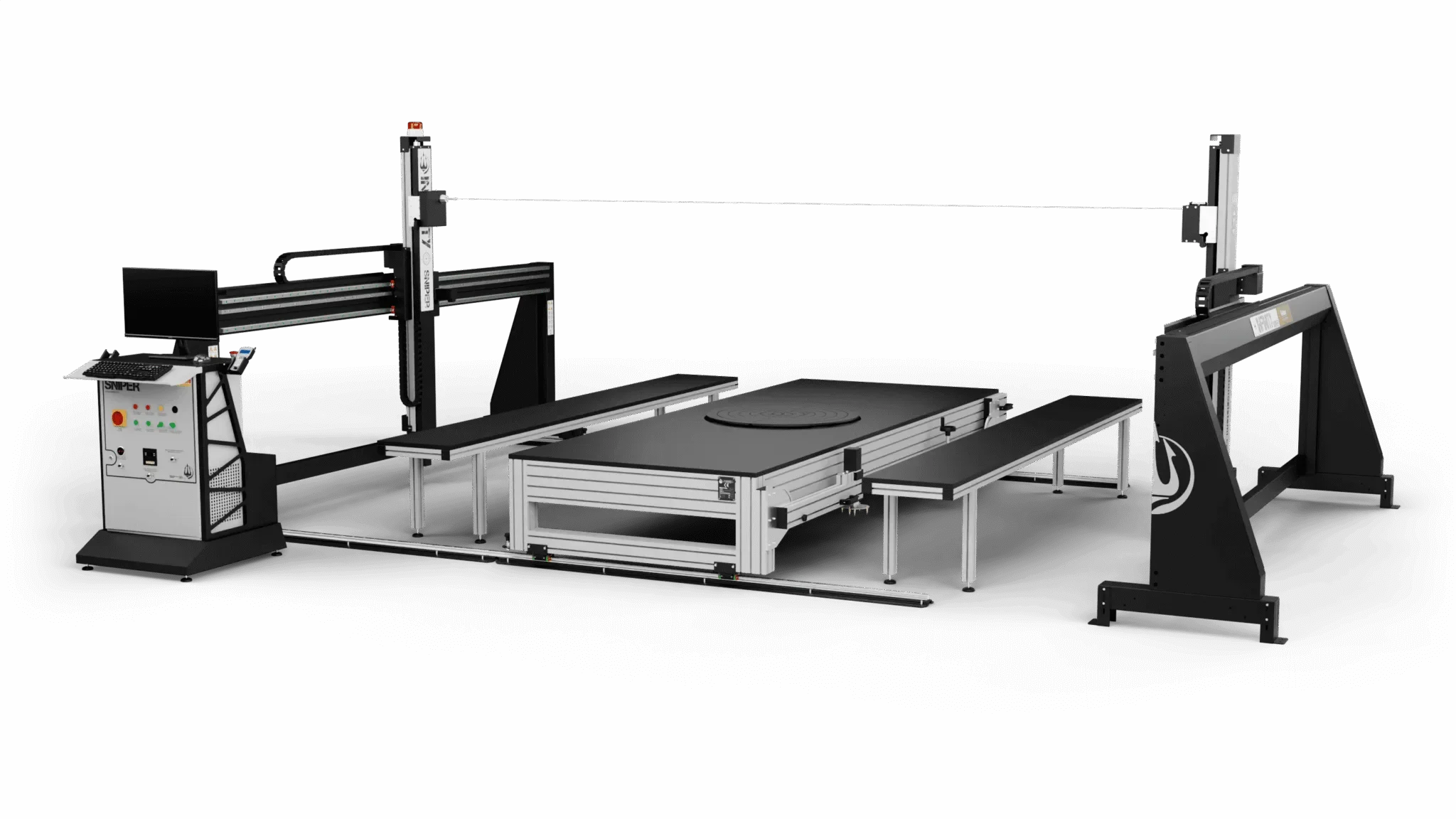

Precision Cutting Technology

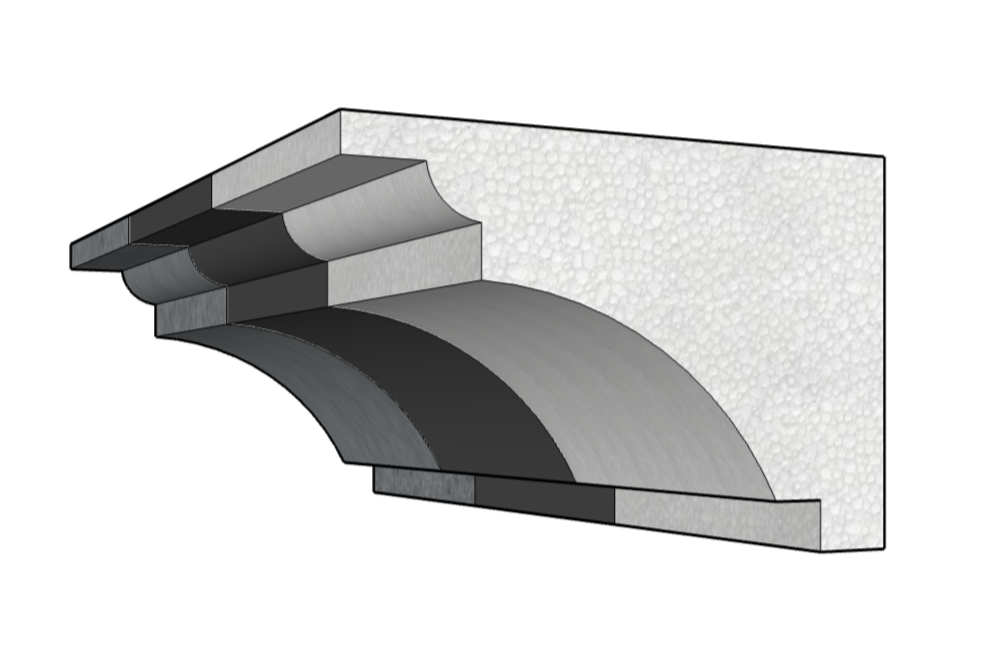

We utilize a sophisticated Nettuno Systemi hot wire cutter to translate CAD designs into physical reality. This specialized equipment allows us to carve complex and intricate architectural foam shapes (such as cornices, moldings, window bands, and columns) out of large EPS foam billets with exceptional accuracy and minimal material waste.

Advanced Reinforcement:

For superior durability and structural integrity, our shapes undergo critical post-processing steps so your installers don’t have to. This includes the precise application of fiberglass reinforcing mesh—a crucial component for impact resistance and stability.

Protective Basecoat Application:

Finally, a carefully formulated basecoat is applied directly over the mesh. This creates a smooth, hardened surface that is ready for finish application upon arrival at the job site.

Why Choose FoamWorks?

15+ Years of Industry Expertise: We know EIFS installation inside and out.

4 Years of Process Development (FoamCAD legacy): Our methods are proven to deliver consistency.

Guaranteed Quality: Precision-cut and pre-coated shapes reduce job site labor and errors.

EIFS Compatibility: Our finished products are designed to integrate seamlessly into your building's EIFS, ensuring a cohesive, beautiful, and energy-efficient exterior.

Choose FoamWorks for your next project and experience the difference that dedicated precision and installation-level expertise can make.